In a perfect world, your power supply would never be exposed to harsh conditions and it would run smoothly, enjoying a long, useful power supply lifespan. However, that’s not the reality.

Many applications require power supplies in environments where moisture and dust are commonplace - from powering the lights in greenhouses and grow rooms to protecting your premises with security cameras, keeping your manufacturing equipment running, and more.

That’s why you need to take note of the specific protections your use case demands. This can get complex given the nuances between NEMA and IP ratings, which is why we created this comparison guide. So, what’s the difference between NEMA vs IP ratings?

These both speak to the level of enclosure protection a power supply has. They’re just different organizations, one being the National Electrical Manufacturers Association (NEMA) and the other being Europe-based International Electrotechnical Commission (IP).

Even within each of these ratings you’ll need to understand the different levels of protection you have access to. We’ll help you navigate all this below because here at Bravo Electro, we’ve curated an AC DC power supply and DC to DC converter selection for any application.

So if you just want to skip ahead and find the perfect power supply for your specific application, don’t hesitate to reach out - we’ll talk over your needs to give you a personalized suggestion!

The Importance of Enclosure Protection for Power Sources

Before we compare and contrast IP vs NEMA ratings let’s take a step back and discuss the need for enclosure protection in the first place. After all, not every use case needs the same level of coverage.

Power supplies are the heartbeat of your operation, and any failure means costly downtime. You can’t afford this. You don’t want to deal with the hassle and costs of premature power supply replacement, either.

Since these power supplies that keep your business running are so vulnerable to dust, moisture, and physical impacts, proper enclosure protection is non-negotiable in certain applications. This prevents malfunctions, reduced efficiency, or even complete power supply failure.

This is especially important in industrial, outdoor, or hazardous environments where power supplies are exposed to extreme temperatures, chemicals, or water.

Fortunately, you can enjoy peace of mind choosing the right power supply equipped with the optimal NEMA (National Electrical Manufacturers Association) and/or IP (Ingress Protection) ratings.

Tightly sealed gaskets, or in some cases, seam welding, prevent a certain level of dust or moisture from infiltrating the internal components of your power supply where they could wreak havoc.

The only question is, how much protection do you need? This is where understanding NEMA vs IP ratings becomes so important. So, let’s take a closer look at the ins and outs of each rating system.

NEMA vs IP Ratings: What are the Differences?

Both systems categorize an enclosure’s level of protection against environmental elements, but they use different methods and focus areas for classification. Choosing the right one isn’t just a matter of compatibility - in some cases, it could be a compliance issue.

Overview of NEMA Ratings

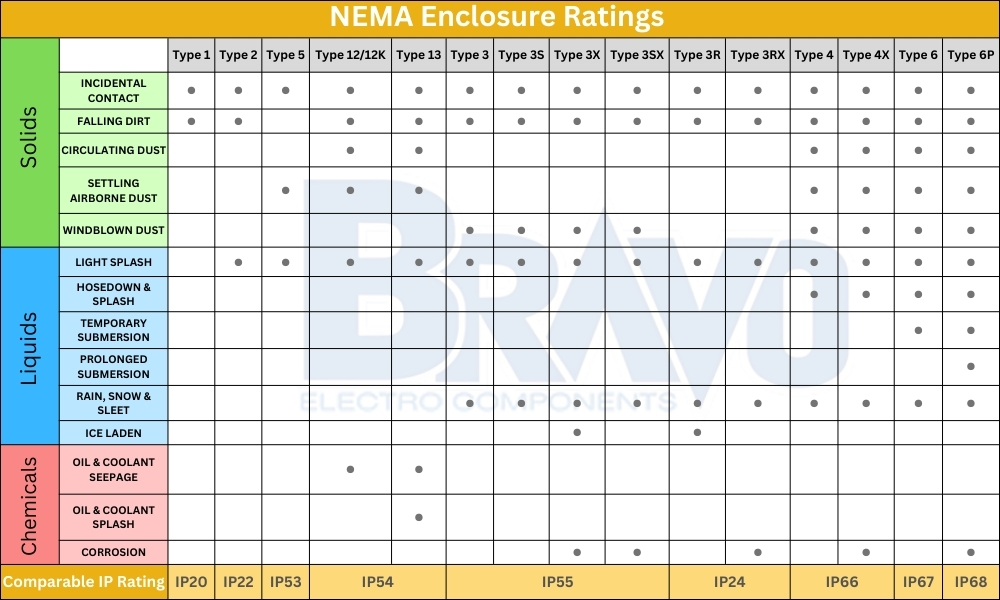

NEMA ratings are an American standard and thus are mainly used here in North America. These ratings define how much protection an enclosure provides against environmental conditions such as dust, water, chemicals, and physical impacts.

NEMA ratings also assess the enclosure’s ability to protect personnel from hazards inside the enclosure, such as live electrical components. The scale ranges from NEMA 1 to NEMA 13, each with specific characteristics. These are the most common ratings to be aware of:

- NEMA 1: Basic protection against contact with internal electrical components and limited protection against falling dirt. It’s commonly used in indoor applications with minimal environmental hazards.

- NEMA 3R: Designed for outdoor use. It protects against rain, sleet, and external ice formation, but not dust or windblown particles - at least, not fully.

- NEMA 4: More robust protection against windblown dust, rain, sleet, and splashing water. This rating is suitable for both indoor and outdoor applications but is most frequently used in industrial and harsh environments.

- NEMA 4X: Similar to NEMA 4 but with added corrosion resistance. It’s ideal for environments with chemicals, saltwater, or corrosive substances which is why you’ll find it most commonly in marine applications or chemical processing plants.

- NEMA 6P: Provides the highest level of protection, including long-term submersion protection in water or other liquids. This rating is optimal for specialized applications like offshore platforms or underwater cables.

- NEMA 12: Commonly used in industrial applications to safeguard from dust, dirt, lint, and dripping water. It’s perfect for indoor environments with moderate exposure to contaminants.

Each NEMA-rated enclosure undergoes strict testing to meet the specified standards. These tests may include exposure to water, dust, or corrosive agents, as well as tests for impact resistance and durability.

For many organizations, staying compliant with NEMA standards is the top priority as it can all but guarantee the longevity and safety of their electrical equipment. But, is this is the right standard for you, or do IP Ratings hold greater weight?

Overview of IP Ratings

Let’s look at the other half of the NEMA vs IP ratings comparison. The IP rating system, formally known as Ingress Protection or International Protection rating, is a more globally recognized standard used not just here in the states but in Europe, Asia, and many other countries.

It also classifies the degree of protection an enclosure offers against solid objects and liquids, like NEMA. The IEC (International Electrotechnical Commission) is the governing body for this international rating system.

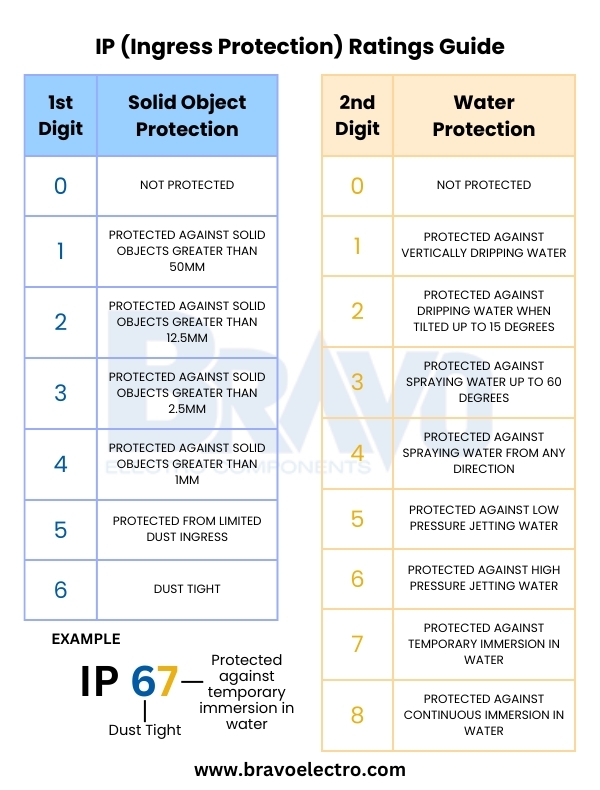

What makes IP ratings unique is the structure of the ratings themselves. Every IP rating consists of two numbers, each of which tells you how much protection you’re getting against certain risks.

The first digit defines the level of protection against solid particles, such as dust. The second digit speaks to the protection against water ingress. Each is important, but the level of protection you need against one or the other will depend on your specific application:

- IP20: Offers some protection against large solid objects, but no protection against water, so it’s only suitable for indoor environments where liquid exposure isn’t a concern.

- IP54: Partially protects against dust and water splashes from any direction. It’s typically used in moderately exposed outdoor applications.

- IP65: Full protection against dust and protection against water jets from any direction. It’s the go-to in outdoor environments with regular exposure to harsh weather conditions.

- IP67: Provides complete protection against dust and temporary submersion in water, making it ideal for harsh outdoor or industrial environments.

- IP69K: The highest level of protection. It’s resistant to dust and high-pressure, high-temperature water jets. It’s normally used in industries like food processing where frequent cleaning is required.

There are quite a few other IP ratings as well, but these are the most common. The first digit can range from 0-6, whereas the second digit can range from 0-8.

The IP rating system offers more precise, clear information about exactly how much protection you’re getting from dust and water. Because it’s globally recognized, you’ll find that IP ratings are more common than NEMA ratings.

The IEC lays out its own stringent protocols for testing IP ratings. Solid particle tests involve exposure to various sizes of dust and debris, while water ingress tests may involve spraying, immersion, or pressure washing.

Which is Right For You Between NEMA and IP Ratings?

There’s not necessarily a right or wrong answer as to whether NEMA vs IP ratings are better - they provide different information. Sure, they serve the same purpose of providing protection for electrical enclosures against environmental hazards. The scope varies, though.

NEMA Ratings offer broader protection, often including considerations like corrosion, ice formation, and personnel safety. In contrast, IP ratings remain more focused on dust and water ingress with a more clear, quantifiable assessment of protection.

When in doubt, consider whether your specific industry or application has unique recommendations or even compliance requirements. Here are a few examples of when NEMA and IP ratings are used:

- Oil and gas: NEMA 4X or NEMA 6P might be required for corrosion resistance and submersion protection in these rugged environments.

- Medical devices: IP ratings like IP67 or IP69K are common in medical settings due to the need for protection against liquids and dust and the slim margin for error. The importance of medical power supplies working well around the clock can’t be overstated.

- Manufacturing and automation: IP ratings are typically used to protect delicate electronic equipment from dust or water splashes in factories or assembly lines.

So, think about your application. If the enclosure is in an area where water and dust are the primary concerns, an IP rating may suffice. However, if the equipment is exposed to harsher conditions, such as saltwater or chemicals, a NEMA-rated enclosure is more appropriate.

Either way, you can rest assured Bravo Electro has you covered. If you’re still wondering what power supply you need, don’t hesitate to reach out for one-on-one assistance choosing between IP enclosure ratings vs NEMA ratings!

Bravo Electro Has the Perfect Power Supply for Any Application!

We hope this comparison of NEMA vs IP ratings has left you with a clear understanding of which level of protection you need. If not, though, you don’t have to play the guessing game. Bravo Electro is here to provide world-class service, helping you narrow down your options.

As your trusted choice for all things power supply, you can rest assured we have the full range power supplies equipped with any NEMA and IP ratings you need.

We have a great selection of harsh environment power supplies and harsh environment LED drivers, all of which have some level of IP rating. They’re sourced from industry-leading power supply manufacturers such as MEAN WELL, so you can shop with confidence knowing you’re getting the efficient, reliable quality you deserve.

We have all the common types of power supply you could need, too - be it a DIN rail power supply or modular power supply, external power supply, LED driver power supply, or anything in between.

Chances are one of our standard offerings will suit your requirements. But if not, don’t sweat it - we have an intuitive custom power supply program that allows you to tailor one of our off-the-shelf solutions to your exact needs for less than you might think! It all starts with a conversation, so get in touch today.

With the best selection of PSUs from trusted brands, exceptional customer service every step of the way, and the lowest prices online, what more could you ask for?

Take the next step today as we wrap up our NEMA and IP Ratings comparison.

Bringing Our IP vs NEMA Ratings Comparison to a Close

There you have it, everything you need to know about the nuances between NEMA and IP ratings. While each serves the same purpose of defining the level of protection an enclosure provides against environmental hazards, NEMA and IP ratings are very different.

NEMA ratings provide a broader scope, covering not just water and dust but also corrosion and ice resistance, while IP ratings give a precise measure of ingress protection from environmental elements. Only you can determine which is right for you - unless, of course, you get in touch with our customer service team.

Our blog has additional resources on power supply making buzzing noise, advantage of having a redundant power supply, how to check PSU wattage, linear vs switching power supply, how to fix power supply, LED driver failure symptoms, power supply efficiency, power supply specs, DC DC converter efficiency, types of power supply connectors, how to install a new power supply, and more.

Whether you’re on the hunt for the best modular power supply or a low profile power supply for tight spaces, remember that Bravo Electro has you covered. You can narrow your search based on power supply voltage below:

Protect your equipment with confidence. Browse our collection of top-rated power supplies designed to meet NEMA and IP standards, and let us help you find the right fit for your industry and application!